-

Posts

4,258 -

Joined

-

Last visited

Content Type

Forums

Profiles

Events

Store

Posts posted by IHAVEGAS

-

-

1 hour ago, -JCN- said:

I think they should allow optics on Revolvers in Revo division.

Do they hold up with wheel guns? My S&W 929 can't shoot some factory target ammo (federal for example) because the recoil impulse shakes the bullets out of the brass.

-

23 hours ago, Racinready300ex said:

So the handful of diehard 10 round guys

I wonder if that effectively translates into, the majority of people who would be effected by the rule change? Don't know, not implying, just wondering.

-

8 hours ago, JWBaldree said:

As a former Production shooter, I'm not really seeing a huge advantage to 15rds, except for maybe some short and medium COFs. At best it is saving one reload per stage. 15 rounds means 2 reloads for a 32rd COF, instead of 3 reloads for 10 rounds.

That is not the way things work out. The fewer rounds you have the more rounds you leave in the magazines so that you do not have to risk a standing reload for a make up shot or run a plan that avoids the standing reload but costs time. Now and then it is only 2 or 4 shots & then swap mags so you are ready for that next group of targets when you get there.

9 hours ago, Boomstick303 said:I really do not understand the organizations aversion to switching Mag Capacity of various divisions.

It makes the game entirely different. If you enjoy the challenge of more intricate stage planning, hitting reloads slick, and not going to war with that challenging shot because you can't spare the make up shots, then you prefer low capacity. If you want to make things as easy as is possible then you prefer high capacity.

I don't think there is a right way and a wrong way to enjoy the sport, but folks do definitely have their preferences. When I last shot limited instead of production I felt like I was cheating myself out of half of the fun of the game.

-

11 hours ago, sharko said:

Picture?

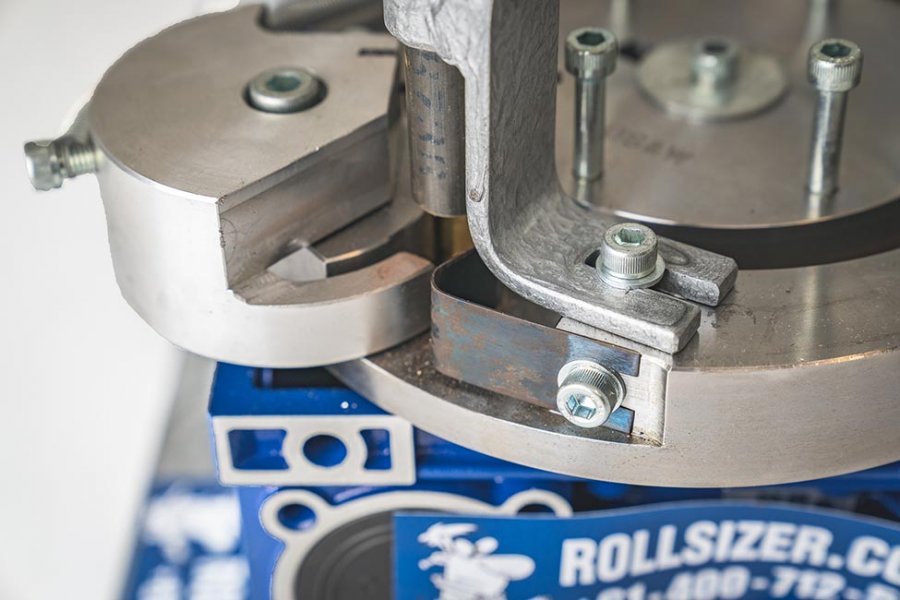

I know you figured it out but I figured I'd throw in a pic for anybody else interested, should have from the start. On this one it looks like they got the bend right and the slot width is right for the screw and washer. Mine has a large slot which will be ok after I run to the hardware store and grab a large thick washer, and doesn't eyeball as a true 90 degrees and is painted differently.

10 hours ago, 67isb said:

10 hours ago, 67isb said:I ended up using a small cut piece of silicone cooking sheet to keep it from moving around. This was my temporary workaound until I can fix it myself.

Good info. Will Rube Goldberg with the thing if I have to but for what it cost I am going to see if the manufacturer will make it right (it is only a week or 10 days old).

Thanks all.

-

Best I can tell the drop tube bracket for my roll sizer was redesigned at some point. The original version I think was this one.

My bracket, just received, is a bent piece with a fat slot rather than what appears to be a welded piece with a slot that fits the bolt well.

Not fussing about the redesign, but right now the only issue I have with my machine is that I can't get the bracket to stay in place for long even with the screw tightened as much as I dare so I'm wondering if that is part of the problem.

Any advice appreciated, 9mm is what I run.

-

2 minutes ago, sharko said:

the one with the metal plate on the side I assume your talking about.

Yep.

-

20 hours ago, ltdmstr said:

As for the rollersizer not working if cases are lubed, that makes zero sense because as long as the cases are rotating as they go through the dies, as compared to sliding through, it's doing what it's supposed to do.

I can't explain it. With stuff like this I tend to think of a multi million dollar hydraulic press system my company purchased the rights to. Corporate engineering went through the drawings and eliminated everything that made little sense, after they built it it would not perform as promised, eventually the designers of the press reviewed the improvements and determined that we had taken their revision 3 design and modified it to very closely match their original design.

Long winded way of saying that sometimes experience shows you what you wouldn't think of. Perhaps that thought does not apply in this circumstance, do not know.

Cleaning the oem Dillon shell plate only kept things jam free for about 1,000 cases. Seems like only a very slight amount of the black crud is enough to cause problems. Anyone know if the double alpha shell plate helps with jams on the old two speed Dillon case feeders? The shell flipper that comes with the plate does not work with the older Dillons so I don't know if the AA plate would help with jams.

-

14 hours ago, sharko said:

Kevin from Rollsizer gave me some tips on the case feed.

All of which look interesting and may help me down the road. Thanks to all for input.

For what it is worth, I am a dummy sometimes. In the picture above this post you see the black rings on the drop tube that are from transfer of lube and etc off of the cases. My case feeder had that black gunk all over the exposed surfaces that contact brass inside the bowl and on the shell plate, I had not cleaned that area in years. I cleaned everything well with goo-gone, particularly the holes on the outer edge of the shell plate. Since cleaning I've only run about 800 rounds but I have not had one jam, which is a step change, and the plate seems to be dropping shells faster (a higher percentage of the holes in the shell plate are full).

Before buying the roll sizer I would have benefited from cleaning the feeder, but my reloading is so much slower than feeding the rs that cleaning the jams wasn't really enough of a nuisance to fret over.

-

45 minutes ago, sharko said:

When I first got mine it was constantly jamming,

9mm only.

Mine drove me nuts for a while until I rotated the drop tube holder farther forward (downstream) than what looked right to me. Now, as you said, the thing that keeps me from being able to walk away from it is my Dillon case feeder (all stock).

Will look into the AA shell plate, but if I wasn't such a fussy fart it all is plenty good as is, I just have to multi task nearby so I can hear it when the shells stop rattling and I need to fiddle with the feeder a moment. Before spending money I am going to clean the Dillon shell plate thoroughly and see if the coating of lube and gunk on it from lubed brass is part of the problem.

Fun so far!

-

Got mine yesterday. A couple limitations from reading the manual that I hadn’t noted elsewhere.

1. If your brass is already lubed the manual says it won’t roll size correctly. No biggie, I just happened to have a bunch of lubed brass that I suppose I need to clean again.

2. If you let the roll sizer run empty you have problems with jams. In my case that means I need to slow the roll sizer down below the maximum speed that my Dillon case feeder drops brass and be more attentive to the process than planned.

3. ?

-

10 hours ago, HesedTech said:

Obviously you didn’t get the humor.

Correct, it would never have occurred to me that you meant something derogatory about my home. Regardless, you meant it as a lite hearted remark so it is all good.

-

11 hours ago, HesedTech said:

If your home or dwelling is still using "fuses" then there are greater things to worry about than the Rollsizer.

Hmmm. I'm an electrical engineer who has spent 30 years working with maintenance electricians if that matters, anyway, we can agree to disagree. Resetting breakers is certainly more convenient and both have a good track record, I will grant that.

-

I am a worrier so I wanted to make sure that I run one of these fellers without blowing fuses.

Got a quick response from the manufacturer, thought somebody else might be interested.

"Good question.....not many ask this.The commercial machines are TEFC single phase 370w x 110vac. They are fitted with a Nema 5-15 earthed plug for 15A rating.They pull about 11A on DOL starts.They are rated for 50Hz so will run comfortably on 60hz. " -

Good stuff, thank you!

-

On 5/30/2023 at 7:41 PM, JWBaldree said:

I had this last weekend, as the peanut gallery was getting loud over something or another and my shooter was having a hard time hearing my commands. No biggie, it's a gregarious group at my home club. I just politely asked if they could tune it down a notch. Problem solved

Makes sense.

A lot of times at locals, and even somewhat at majors, a lot of butt hurt can be avoided if you are able to squad with like minded shooters.

There is nothing wrong with being one of the deadly serious folks who would like utter silence, and there is nothing wrong with being one of the folks who is there strictly for the fun and camaraderie. Irritation comes about when you are the casual person in the serious squad or vice versa.

-

12 minutes ago, kurtm said:

If your really interested it's all here, but you will have to dig around yourself to find it.

There must be 10,000 (100,000?) places on this site where people have contributed helpful links to information that they found valuable on Enos or elsewhere on the internet. I agree that you can do things the other way if no one has guidance or if that is what you prefer. -

There always has to be one . . . .

If anyone cares to contribute a helpful answer that would be appreciated.

-

I am thoroughly ignorant about tactical shotguns and have never even owned a semi auto shotgun, always either shot a pump or double barrel when hunting.

Got the notion that an M2 properly set up for 3 gun would be a fun range toy and a nice upgrade for home self defense so I ordered one, went with Hawkeye Ordnance, wanted somebody with know how to get things started right.

Looking for a 'things to tell newbies that I wish I had known' article if there is such a thing. Any guidance appreciated.

Other thing - entirely unrelated - maybe just weird. Was at a steels match yesterday and got to wondering if any club level matches allow you to shoot steels 2 gun. You'd have to bring your own bucket but it seems like it could be a lot of fun and good practice to shotgun and then switch to pistol for the occasional longer range shot or vice versa.

-

On 3/14/2023 at 10:30 PM, Fishbreath said:

My big springtime project this year was recording everything I've learned about tuning up GP100s.

Having tried Olhasso's trigger at the IRC, I think he does better than me, but not by very much. Hopefully this is useful if you have a GP100 you're interested in slicking up.

In a word.

WOW!!!

My life should slow down in a month or so and I want to take this on as a project.

Would you mind a quick reminder of what the final result was in pull weight with federal primers, I am sure it is there or here somewhere, just being lazy.

-

On 9/11/2022 at 10:47 AM, zzt said:

There was some discussion of this at the match yesterday. One of the shooters said that every shooter using CZ mags with extensions failed the gauge test at the chrono station. TTI extensions were specifically mentioned. I don't know if it was +4 or +2 extensions.

When the TS Orange guns were fairly new a friend had a similar problem. I think the lesson he learned was to gauge check himself rather than trust the extension manufacturer.

-

-

3 hours ago, ltdmstr said:

for that extra money they'll get a superior product that functions better, lasts longer, looks better and has a better resale value.

The other big component to cost is customization. For my nickel the best value is with well built factory guns (CZ TS for example) seconded by the "blue plate special" (Baer, Wilson, Triangle, etc) semi customs. Full custom is cool if you can afford it and if having something a bit unique is valuable to you.

-

8 hours ago, Johnny_Chimpo said:

People can move on with progress or they can get left behind.

I guess I'm the latter. Still love a V8 car and a V-twin bike, still prefer Iron sight semi autos & revolvers.

-

5 hours ago, Fishbreath said:

Maybe the second 9mm will go straight to him, then, when I find it!

I think we're both shooting revolver at MD State, albeit not on the same squad—maybe I'll see if he'll let me try the trigger a few times at the safe table.

I'm skeptical that he has found a magic trick for the same Ruger action that has been around for several years and tinkered with by many revolver smiths, but sometimes discoveries happen. Will be interesting to hear about it if you get to check out his gun.

New USPSA Survey

in USPSA/IPSC Shooting

Posted

I only have one friend that shoots a 929 so I can't provide a lot of data, he had the same issue. Federal target ammo 115 grain. Do not know how much the lack of a slide/recoil spring changes things.