-

Posts

1,789 -

Joined

-

Last visited

Content Type

Forums

Profiles

Events

Store

Posts posted by HOGRIDER

-

-

On 8/20/2020 at 4:07 AM, stick said:

Have you tried to reverse engineer the load? Pull the bullet, measure the powder and develop a similar load. The other snag might be determining what powder they use.

stick:

I definitely thought about that..........however, I doubt that Federal or any of the other major ammo manufacturers are using over the counter powder such as what's available to us! From what I've read, they primarily use powders that are custom blended on a commercial basis..........

Thanks!

-

Thanks for all the feedback/replies!

My game plan is to chrono/test a few rounds at 3.6, 3.7, and 3.8g using the N320. Since 3.9 is the published max, I feel if I need to explore higher velocities/power factors, I'll have to try a different powder. Or break down and try some 124g/125g FMJs. Since I have several thousand 147g Zeros and Coated lead, I hope to find that sweet spot for both.

Of course, I also have COAL to play with. Trying to standardize with 1.125" since the STI loved the American Eagles at that length; but could always go longer. I'm sure the STI would tolerate 1.150" if necessary.

Again, thanks for everyone's replies!

-

There are too many variables. Why didn't you post a picture of the N320 group? What type of accuracy difference are we talking about? Is it a shotgun pattern? How much accuracy do you need? Bullseye? IPSC? A ransom rest is great for testing but you'll never be able to duplicate those results by hand, so why worry? The most significant accuracy gains you'll ever achieve will come from practice.

The primary purpose of this Chrono Session was to get a baseline of velocities since this was a new load workup. Of course I would have noted if accuracy was acceptable for a simple bench rest setup. And yes, I fully understand the operation of a Ransom Rest and WOULD NEVER think I could duplicate the results by hand!

P.S. Generally, the faster you send them the more accurate they'll be.That's what I primarily hoped to establish with this thread. Am also looking for feedback as to why this pistol loves to be ran in the 149+/- Power Factor Range!

P.P.S. Don't bother with .1gr increments, use .2gr or .3gr depending on the size of the charge window.The window for this powder/bullet combo is 3.1g - 3.9g according to Vihtavuori's most current data. Hence my reason for starting out at 3.5g.

My thinking is that pushing this combo just a bit faster may prove to be the sweet spot that will yield a minor load with (my) acceptable accuracy standards.

-

Attempting to develop a load for the STI 4.15". Starting with a mid-range powder weight, I'm seeing these results:

3.5g N320, 147 Zero JHP, WW Case, Fed SP Match Primer, COAL 1.125”

Temperature: 74F

Pressure: 30.1 in Hg

Bullet Weight: 147

Number of Shots: 10

Pressure: 30.1 in Hg

Bullet Weight: 147

Power Factor Average: 130

Power Factor Low: 128

Power Factor High: 131

Number of Shots: 10

Minimum: 873

Maximum: 897

Spread: 24

Average: 885

Standard Deviation: 6I've been searching, with no luck, for a couple of older posts where IIRC seasoned veterans stated the 147s liked faster velocities. But I'm just not sure...........

This above load felt fine, accuracy was ok. For some reason, I think I should try 3.6g and 3.7g. I always strive for accuracy first within 20-25yds.

What still has me confused is why this gun/barrel likes the faster velocities! (See Attachment) It's favorite load so far for accuracy has consistently been the Federal American Eagle AE9FP. Chronos with these results:

AE9FP 147g. Published 1000fps Chrono @ 10’ Target @ 20 yds

Temperature: N/A

Pressure: N/A

Bullet Weight: 147

Power Factor Average: 149

Power Factor Low: 149

Power Factor High: 151

Number of Shots: 10

Minimum: 1014

Maximum: 1028

Spread: 14

Average: 1020

Standard Deviation: 5Guess my biggest concern is can I develop a similarly accurate minor power factor load with my current components of N320 and Zero 147 FMJ?

Appreciate any and all feedback!

Thanks,

Ben

-

15 hours ago, jeremy kemlo said:

Those 2 articles are great. Based on that I need less crimp and a little shorter oal.

jeremy:

Lee64 has also provided some excellent information above!

-

27 minutes ago, SteelCityShooter said:

I've tried every maker's variation of the "Vibra Prime" primer tube loader (Hornady, Frankford Arsenal, etc. ) and none of them were reliable. They would constantly jam primers into the exit chute no matter how carefully it was held and deliver an unacceptable number upside down. I contacted the makers, followed their recommendations and nothing helped. Apparently my experience was not unusual as they disappeared from the market pretty quickly.

Not sure if your "every maker's variation" includes the Pal Primer Filler.................

Purchased one based on my research here, and it's yet to produce an upside down primer; nor has it been anything but super reliable!

https://forums.brianenos.com/topic/244660-pal-filler/

-

1 hour ago, jeremy kemlo said:

Working up a new load. Will try it out on saterday. Amy one shooting this combo that could give me feed back as to what worked for then or it I should adjust anything before heading to the range.

Shadow 2147 bayou Bullets flat point.

3.35 of n320

brass belled to .383 with ssi alpha powder dropper.

1.143 oalcrimp .375

From my notes for a Glock G17G4 with Bar-Sto Barrel:

Bayou 147 Coated FP

3.2gr N320

Avg: 893fps

ES: 17

SD: 4

OAL: 1.120"

Excellent Accuracy. Was normally belling to .382 with DAA powder funnel. ALWAYS crimped to .376"-.377".

IMO, your crimp is a bit too much. May want to pull a few bullets and check for scraping of the Bayou coating. Read this:

https://czfirearms.us/index.php?topic=78873.0

PS: 1.142 is a fine COAL as long as it fits the chamber of your Shadow 2!

Check this:

https://czfirearms.us/index.php?topic=103620.0

-

13 minutes ago, Ollies930 said:

That seems really dangerous. Bump it and it would go off. It was always my impression that the sear is supposed to match the trigger surface at the very least or better yet go the other way a little bit.

Transposed from the original blueprints with early modifications..............

Correctly modified sear/hammer angles and surfaces can result in less than 2# pull weights and be perfectly safe for thousands of rounds!

-

13 minutes ago, ltdmstr said:

Not exactly. Depends on the depth of the secondary angle cut on the sear. It's going to be something less than full contact, so less than .018.

Good point!

From the pic attached, we can see if the hammer hooks were .018", then the primary angle of the sear may only contact .014". That's secondary angle on the sear face will determine depth of engagement.

-

-

14 hours ago, RangerTrace said:

In my experience, the worst 1911 trigger feels and shoots better than the best Glock trigger.

Absolutely!

-

1 hour ago, DryHeat said:

Hogrider.

You mention removing the spring, I had not thought of that, thanks for the tip. I will try and see if it helps. You also mentioned to make sure the shell plate is full and then final adj?? Do you mean I should bottom the die against the shell holder, I am using a single station press for this operation. Does the shell plate do the same thing in a progressive loader. I picked up on that from another contributor a couple of weeks ago, maybe it's helping I can't tell yet. Back to the spring, if I am seating a jacketed bullet FMJ or JHP the Redding die seems to work it's best. The real issue, the issue that got me here for help, is with coated bullets. When I seated coated bullets I had my greatest variation in COAL. The problem didn't stop there, every once in a while, 8 or 10 cartridges the seat die would make a loud snapping noise, as if the coating had a "Sticky" property to it. My bullets don't feel sticky but I also remember the feeling of the slide being harder to pull back with a coated bullet sometimes. My guess is there is a variation in the thickness of the coating on the ogive of the bullet. I can't measure much difference on the diameter, .0005+- with a really good mic. I don't think it has to do with dia. it seems like the ogive. All I see to do is seat deeper for a safety margin and watch the powder charge because of the deeper seating. Thanks for any ideas.

Dry:

I took it for granted you were on a progressive! Sorry, but if you using a single station press for this op as you stated, then simply use the setup instructions that came with your die. There's also a .pdf for setup on Redding's website.

After loading thousands of coated bullets, I have never had any "sticking" issue with the various brands I have used. I'm assuming the snapping noise happens when the seated round just begins to exit the seating die? IMO, if you had sticking/snapping caused strictly by the bullet, there would be some sort of markings/indentions on the ogive! Only time I have felt resistance in the seating die was either due to over-belling the case mouth which causes the outer case edge to rub against the inside of the seating die body. Or, there was not enough expansion of the case mouth to allow the bullet a smooth transition into the case body while seating. Make up a few dummy rounds (no primer or powder) then knock the bullet out of the case and look for scarring/scraping of the coating away from the lead core. Also, take a permanent marker and blacken the walls of the case to see if anything is contacting the brass.

What diameter coated bullets are your loading? Definitely makes a difference...........

If your trying to load for 12 different pistols, your off to an extremely challenging process! My recommendation is to find a load that shoots well in YOUR TWO PISTOLS and document/test for a common load that shoots well in both. DO NOT seat deeper for a "safety margin"! Use this information to find a COAL that fits and functions in BOTH YOUR GUNS:

https://czfirearms.us/index.php?topic=34225.msg189131#msg189131

Then while checking and double checking the info for your particular powder, primer, and bullet combo at your DESIRED COAL, load up a sufficient number of test rounds and follow Memphis Mechanic's advise and TEST THOSE LOADS!

Make sure you use a QUALITY case gauge and/or YOUR PRIMARY gun barrel to check each and every round until you get these issues resolved.

Once you've developed loads that work just as you desire in YOUR PISTOLS, use what you've learned and develop loads for the "other 10 pistols"................

Good luck!

-

-

47 minutes ago, chgofirefighter said:

Lots of work went into it but thank you~

That is evident!

-

30 minutes ago, AverageJoeShooting said:

just get a redding competition seating die. Has a micrometer ontop so you set it once and it loads to the same length each time

If you use the Redding Micrometer Seating Die, and check the COAL to .000", there will be variations regardless of what press we're using. One thing that will shrink variances with the Redding Die is to remove the internal spring when seating pistol calibers. Also, when setting the micrometer, make sure the shellplate is full then do final, fine adjustments.

My RL1100 is sporting a complete set of Redding Competition Pro Dies, and they always produce first class ammo!

-

21 hours ago, chgofirefighter said:

Now the question is if the metal of the bolt will be too hard for the primer assembly mechanism, not sure if Dillon has a safety feature for their Cam Guide bolt, causing it to break/snap off when things go wrong.

Rob:

While thinking about this very important point you make about a built in safety feature, I remembered during a short loading session the Lever Arm Bracket worked loose from the primer magazine. Basically fouled up the press as the primer Cam Plate assembly slid down an jammed against the Cam Guide Bolt and the Primer Slide Assembly! The guide bolt held its own and never loosened or cracked. But the press would lock up if trying to go down with the handle.

So, you may have a valid point here...........

-

21 hours ago, chgofirefighter said:

The MK7 Evo is a hell of a press I own the Dillon RL1100 and the Evo, both automated... While the Dillon is an excellent press, the Evo is vastly superior but with that being said they both have their own unique quirks but once they're dialed in, you'll be golden~ I use the 1100 to process brass and ocassional relaoding, while the Evo is my dedicated press...

Here's a short video~

AWESOME setup!

-

59 minutes ago, chgofirefighter said:

Nice! how's it working? and why a spacer since Dillon doesn't use one... I'm curious!

Of course my machine is not automated..........yet.... ;), so don't have a lot of rounds going through the press; but so far the aluminum shim seems to have the stock Guide Bolt spaced out from the toolhead at the right distance. I have no idea if this is even necessary, but since I removed the toolhead ratchet which is 0.137" thick, replacing it with a 1"x1" piece of aluminum flat bar seemed like a good idea. As stated in your quote above, the flat bar is 0.127" thick and makes it very easy to use as a replacement for the ratchet.

-

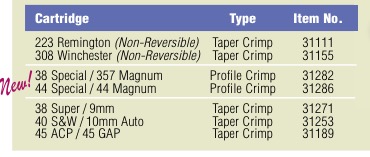

12 minutes ago, 78Staff said:

Isn't Profile Crimp the same a Roll Crimp though?

IMO, yes it is. This is from the chart Redding has on their various caliber Mic taper crimp dies:

-

On the Station #3 expander on "my" RL1100, the upper step is .357", which should be good for most FMJ/JHP quality bullets plus the .356"-.3565" coated lead. IMO, anything (bullets) larger than this will require further expansion at Station 5 via the Powder Funnel.

I still use a modified MBF powder funnel along with the Dillon Expander, and my "sticking" at the powder drop has been 99% eliminated! Tamping of the Zero 147JHP coming out of the DAA Pro Dropper has been extremely stable! Flair at Station #5 is averaging .381" OD.

-

5 hours ago, chgofirefighter said:

Visited my local Home Depot and picked up 2 pre hardened bolts 1/4-20, did a lil magic and this is what I came up with~ I have yet to fully test it out but so far so good, basically my own Cam Guide Bolt DIY~ Now the question is if the metal of the bolt will be too hard for the primer assembly mechanism, not sure if Dillon has a safety feature for their Cam Guide bolt, causing it to break/snap off when things go wrong. I'll report back the results soon! Photos below..

Rob:

I remembered that I had put a piece of 1" aluminum behind my Guide Bolt with the intentions of helping to stabilize..............so far, so good.............

https://forums.brianenos.com/topic/285434-issues-with-rl1100/?do=findComment&comment=3181751

-

The Redding Micrometer Adjustable Crimp Dies have been my choice for many years! Have them in all the calibers I currently reload............

https://www.accuratearmsandammo.com/product.sc?productId=830

-

1 hour ago, TeedOff said:

Here's the one I got: https://www.amazon.com/gp/product/B08127CGGM/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

I also picked up these: https://www.amazon.com/gp/product/B084TZ4KM2/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

I sort of half-assed twist tied the camera so that its looking right down into the case before it goes up into the bullet dropper. I used another twistie thing to "secure" the endoscope cable to the case feeder support. The cable is semi-rigid...enough that it seems to stay in place with no shaking...loaded about 500 rounds with it this way and I'm happy with the view on the screen. Ultimately I'll fab up something more permanent but for now this works. Oh yeah, the monitor itself is set on a stack of die boxes behind the press. As I type this I realize it is ghetto AF, but I just wanted to see if it worked before I spent any effort making it look good. No, I'm not taking any pictures of the setup as it stands today...lol.

Thanks Teed for your input!

Think I'll try the Endoscope route.......if it doesn't satisfy my needs, I'll send it back and go with plan B.

-

3 hours ago, chgofirefighter said:

Visited my local Home Depot and picked up 2 pre hardened bolts 1/4-20, did a lil magic and this is what I came up with~ I have yet to fully test it out but so far so good, basically my own Cam Guide Bolt DIY~ Now the question is if the metal of the bolt will be too hard for the primer assembly mechanism, not sure if Dillon has a safety feature for their Cam Guide bolt, causing it to break/snap off when things go wrong. I'll report back the results soon! Photos below..

Rob:

That sure looks trick! I've got 3 extra Dillon Cam Guide Bolts, but IMO, after talking to other users of RL1050/S1050 machines, it appears the older Guide Bolts were of superior quality compared to the current offerings! Heard that a couple users had the same bolt in machines 20+ years old and older!

I even saw where the "hump" on the rear cam plate had been worn almost completely away on a high volume machine; and it was still using the original Guide Bolt! So, I'm also not sure if there's a safety factor built in to the current bolts.

After talking with Rick about an aftermarket Guide Bolt, I'm just not sure if there's enough interest in covering the expense of creating a billet replacement.................

Anyway, your mod sure looks great! Did you use an SS bolt?

9mm Velocities: Important?

in 9mm/38 Caliber

Posted

Thanks for your feedback!