-

Posts

806 -

Joined

Content Type

Forums

Profiles

Events

Store

Posts posted by 4n2t0

-

-

Primer suck back can usually be solved by gently reshaping the pin with medium grit sandpaper. You can round the pin or I've also had success with a hypodermic needle type shape, like this:

-

You can fill the seating stem to create a matching cavity but that's a lot of work to fix a problem that doesn't (???) affect accuracy.

-

-

Unless the primers are being exposed to extreme conditions a little flaking of the primer sealant won't cause light strikes. Are the primers being seated properly? If so then you probably have a gun problem.

-

-

-

7 hours ago, wick said:

And he ask if he sould invest in somthing different" So I posted my load "

Ewwww....

Keep your loads to yourself!

-

10 minutes ago, wick said:

No WSF is what I ment

Ok...

The OP asked about WST, not WSF.

-

I've yet to see any definitive proof that bullet setback can cause a catastrophic failure. It's a term that gets thrown around when people can't explain or understand how they f*#k3d up.

-

4 hours ago, wick said:

WSF 147FP 3.9gr good 9 load start low and work your load up

Did you mean WST?

-

Something doesn't sound right. What bullet are you loading? What's the case mouth measurement of a finished round? The gauge should allow for a 1.135 OAL. Are you using the gauge below?

-

Don't even break stride, lol, rarely (if ever) would lot to lot differences create a safety issue.

-

I got up to 4.0gr of WST (settled on 3.8gr) with a FMJ. I really like WST in 9mm but I'm saving it for my .38 loads. I currently burn a lot of WSF in 9mm.

Gun: Ruger SR9/9E

Brass: Mixed

Primer: Fiocchi

Powder: WST 3.8gr

Bullet: CamPro 147gr RNFP (Thick plated bullet, manufacturer suggests using FMJ data)

OAL: 1.135

Weather: 25°C

Avg: 891

ES: 16

SD: 6

PF: 130

Gun: Ruger SR9/9E

Brass: Mixed

Primer: Fiocchi

Powder: WST 4.0gr

Bullet: CamPro 147gr RNFP (Thick plated bullet, manufacturer suggests using FMJ data)

OAL: 1.135

Weather: 23°C

Avg: 928

ES: 21

SD: 7

PF: 136 -

5 hours ago, haiedras said:

Agree, your window for N310 is really small...like +.2gr is kaboom! from the pressure spikes.

Can you prove that or are you just talking $hit? Hint: I know it's the latter.

-

The above was not my work, I just cleaned it up a bit. The information above was obtained from "The Original CZ Forum".

-

How to determine a pistols max OAL

ALWAYS FIND YOUR OWN OAL!!! IGNORE THE OAL LISTED IN MANUALS AND DATA, IT'S USELESS!!!

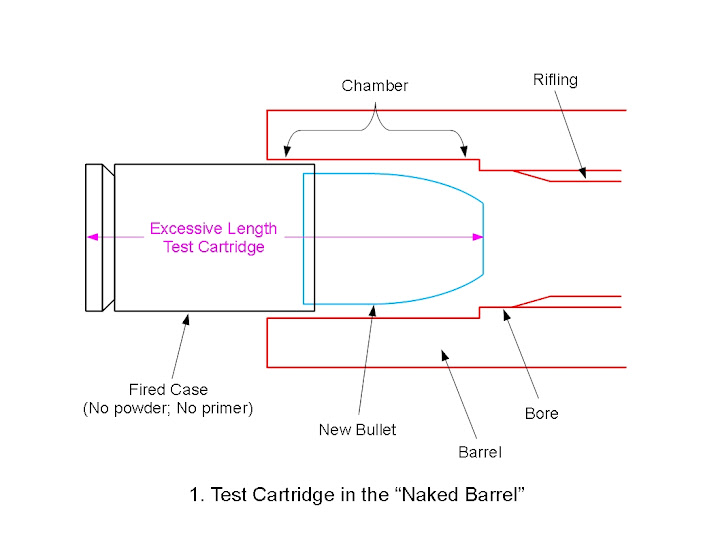

Fit a new bullet into a fired case (just get it started and remember, no powder; fired primer). If you try 2 or 3 bullet/case combinations you'll find one where the bullet is a snug push fit. Working with your barrel removed from the gun slide this test cartridge into the chamber. Push the test cartridge until the mouth of the case comes to rest on the chamber stop. This will collapse the bullet into the fired case.

Slowly and carefully withdraw the test cartridge and measure its new length. Do this several times until you get a number that can be verified.

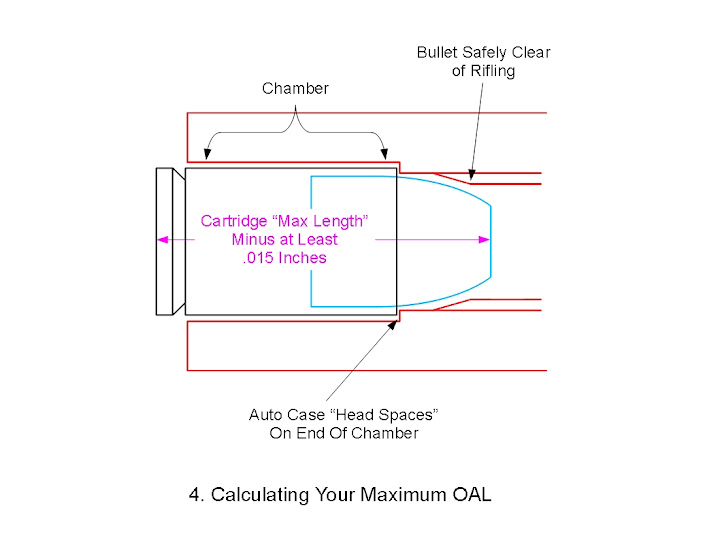

If your test cartridge gives you a number like 1.155", subtract .010" of setback (1.155"-.010"), which gives you a max OAL of 1.145" for that barrel/bullet combination.

Notes:

- If you intend to use your ammo in multiple pistols make sure you load to the shortest OAL obtained.

- Before making an armoury's worth of ammo make sure your rounds plunk and spin in the barrel(s) and that they function properly in the magazine(s).

- Every time you load a new bullet (e.g. Xtreme ---> Zero or Zero 124gr ---> Zero 147gr) you must perform this procedure. The max OAL will change from bullet to bullet because each bullet has its own unique profile. -

I'm voting again....

Shoot it.

-

The barrel length won't affect the safe charge weight range but it does affect performance/function. The longer the barrel the more velocity it will produce. What does this mean for you? If you were looking to achieve a constant bullet speed for 3 different barrel lengths (e.g. 3.3", 4", 6") using the same components for each the 3.3" barrel would need the most powder and the 6" barrel the least.

Below is an example which hopefully better explains my ramblings above:

Safe charge weight range for a 147gr bullet with Titegroup = 3.2gr - 3.6gr

3.3" barrel - 147gr FMJ - 3.6gr of Titegroup - OAL 1.09 = 900 ft/s

4" barrel - 147gr FMJ - 3.4gr of Titegroup - OAL 1.09 = 900 ft/s

6" barrel - 147gr FMJ - 3.2gr of Titegroup - OAL 1.09 = 900 ft/s

-

26 minutes ago, MemphisMechanic said:

This is why. It isn’t exactly unclear what I was adressing.

Yours is the very first instance in which I’ve heard of someone getting a longer OAL with a coated round nose 124/135/147 grain bullet in 9mm than with a coated TC profile of similar weight.

In almost all cases, you can load the tapered cone profile longer. A lot longer. The photo above illustrates why.

Who said I was loading a coated round nose? What's a tapered cone? I've heard of a truncated cone but never a tapered cone.

Are you on the wacky tobaccy? lol.

-

Shoot it.

-

1 hour ago, MemphisMechanic said:

The 125gr TC from Black Bullets or Blue Bullets has an ogive that’s further back than any RN bullet. It’s shaped nothing like a 147 flat point.

Acme’s 124gr RN required me to load shorter than 1.110” to feed my buddies M&P. The exact same gun would take a 125 TC out past 1.150”

Before we throw around statements like “FPs load better than SWCs” or something, we need to clarify exactly whose mold your bullet maker was using!

As an example, it’s obvious that out of THESE three projectiles you’d be able to load the middle one the longest. And that’s the bullet profile I was referring to:

I'm not sure why I was quoted in your reply. Are you having a conversation with yourself? Who said “FPs load better than SWCs”? I think you're a little confused, remember you're the one who posted a general statement that made absolutely no sense, lol.

P.S. We're not mind readers, next time try to be more detailed.

-

On 12/01/2018 at 11:19 PM, mayassa said:

Mine did this also, I tightened the two allens on the plate itself (clutch) and it worked fine for heavier loads of brass.

If the clutch is not allowed to slip (too tight) you'll burn out the motor (or shorten its life span). The manual tells you how to find the appropriate amount of slip. We all want to load massive amounts of brass into the casefeeder but it might end up costing you in the long run.

-

41 minutes ago, Sarge said:

This is why I said last week in another thread that blanket statements don’t mean much when it comes to Reloading. Memphis seems to know his stuff but so much of this depends on the exact bullets used and YOUR gun.

I can load much longer rounds in a given gun using MG 124 CMJ Than I can using MG 124JHP’s. MG RN bullets are very long slender nose where their JHP have long flat sides that will bottom out much sooner.

BUT BBI 135’s RN have a really”bulbous “ shape. MORE LIKE A DOME. They have to be loaded waay shorter than a MG or even a plated XTREME RN.

Exactly my point, that's why Memphis' reply confused me.

-

5 hours ago, MemphisMechanic said:

@M1A4ME and @4n2t0 ... you mean you guys haven’t discovered the hardened lee depriming pins from Squirrel Daddy?

The name is strange, but the product is solid. Bent three factory Lee pins in two weeks time, once.

Can’t manage to hurt the SD one. On anything.

https://www.amazon.com/dp/B018V7L3C2/ref=cm_sw_r_cp_api_rO3xAbV6A92ZG

I use Dillon dies but I've still managed to break/bend a few pins in my day. I get 10 pins for $8 so it's not a huge burden on the wallet.

.png.8933831e314a058d884b6415d09f8720.png)

9 mm bullet puller

in 9mm/38 Caliber

Posted · Edited by 4n2t0

Collet if you screw up a lot, lol, hammer for the occasional mishap. The grip-n-pull is a glorified pair of wire strippers.