-

Posts

693 -

Joined

-

Last visited

Content Type

Forums

Profiles

Events

Store

Posts posted by MilkMyDuds

-

-

I see people dry firing CZs using rubber o-rings on the back of the firing pin to reduce the impact of repeated hammer hitting the firing pin.

CZs firing pin protrudes out quite a bit, allowing the o-ring to stay in place. The Stock 2 firing pin does not protrudes out of the back though.

For folks dry firing their Stock 2s a lot (1 hour/day, 5 days/week minimal), do you take any protective measure to reduce the wear and impacts? If so, could you please share some ideas?

Thanks.

-

As a quantification, I've found that you can dip to as low as 1# 10oz. to 1# 12oz. SA and reliably light off Federal MATCH primers. So do any mod you want, down to that number, and you'll have no issue with Fed MATCH primers.

As for the T3; did you use a sharpie and only take off the ink every time? If you watched my video, and made a pass on the T3 as hard as I did in the video, I can assure you the disco/int is ruined. You also need to function check every time you make a pass on the disco. It should easily reduce your DA pull if you work the angle.

Before I did anything to the T3 disco, I put it on and neither SA nor DA would fall. Then I did minimal removal, barely removed the sharpie mark, still neither SA nor DA would fall. I then did a bit more... so on. I did about 5 rounds of that, and still neither SA nor DA would fall. At that point, I realized the T3 disco is probably already ruined, or, maybe I have not removed enough material?

I guess the key piece missing is, what behaviors characterize not enough material removed, and what would indicate too much have been removed?

-

Thanks for the suggestions. I do not mind running Federal primers exclusively. Have 20k stocked up, but I usually use WSP. Last test on the range the gun ran 350 WSP with 100% ignition. Now with added 1 piece sear and reduced power sear spring, I need to test again. It does look like I could experiment with the hammer springs a bit. Thanks.There are some things. Well worn Wolff 13# hammer spring. EG light one coil cut, 14# hammer spring with a full coil cut off, or wolff 15# spring with 2 full coils cut off. Buy several hammer springs in each poundage snip partial coils until you get your DA where you want it. Do a pencil launch test after each change, run 100 rounds in DA to verify it will fire. Record results, snip a bit more and repeat until it won't tun reliably. Then make a spring with less cut off.

Are you ONLY running Federal primers? With recent messing around, I've seen 6 1/2 pounds with modified 14# and 15# springs. But! They won't reliably set off my S&B primers and I can only assUme the federal match primers will go off.

Do keep in mind, I run about the same pull force you are at so the gun will be reliable with the primers I have. So, I really don't know how well those modified springs will run or last, etc. There are guys here that do run them... check with them on the pros and cons they have found.

-

I received the 1 piece sear and reduced power sear spring.

Did 3rd round polishing while installing them. Polished the new sear piece and all the holes too. 600 grit, 1500 grit and 2000 grit.

Also tried to fit the T3 disco for the 2nd time following the youtube video. Unfortunately from the time no material was removed to the point where a lot of material has been removed, hammer would not fall in neither DA nor SA. Not clear I went past or not enough. Comparing mine to the youtube video, I have about the same amount of materials removed, and I know the guy in the video said "this T3 will be ruined" in order to show the "waves" more clearly.

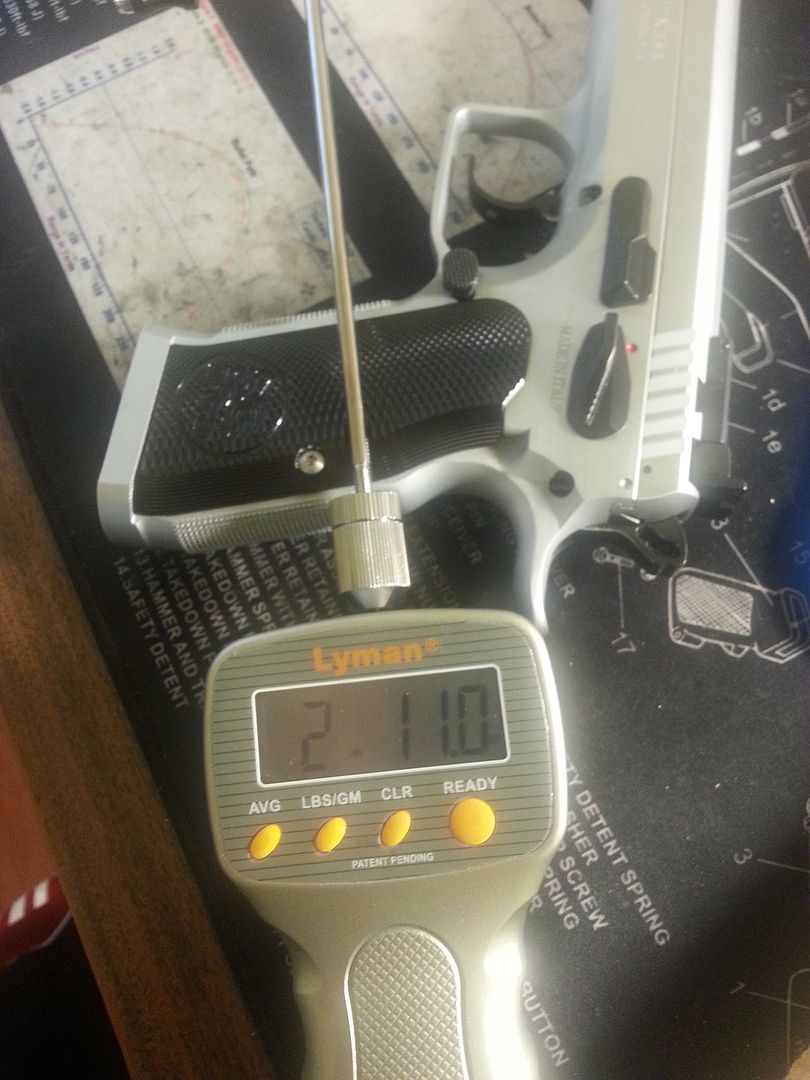

Anyway, I put back the factory disconnector. Now my SA went down to 2 lbs 11 oz - very nice!

So it looks like the 1 piece sear made a huge difference.

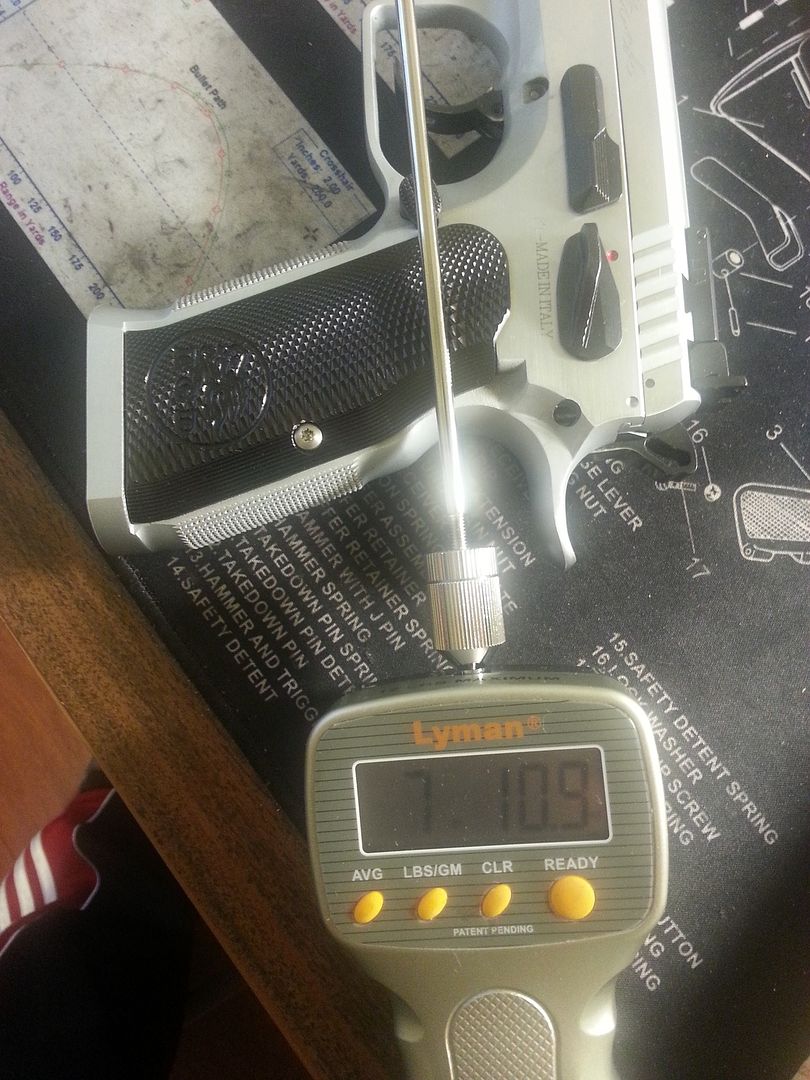

However, my DA is still 7 lbs 11 oz range. I am not sure how to reduce DA pull now. It actually went up from barely 7 lbs to 7 lbs 11 oz after I put in the 1 piece sear.

One thing I found is that using the factory trigger return spring reduces the SA weight by 5 oz over the CGW reduced power trigger return spring. It does not do anything to DA it seems.

Here is what I have in the gun currently:

1. Titan hammer

2. 1 piece sear

3. CGW reduced power sear spring

4. Xtreme hammer spring light (13.8lbs)

5. Xtreme firing pin spring light

6. Xtreme firing pin safety

7. Xtreme firing pin safety spring

8. Canik trigger pin

9. factory trigger return spring

10. BIC click pen spring as trigger plunger spring

11. Woff 9lbs recoil spring

12. Henning guide rod

13. Xtreme firing pin

Any ideas how to make DA pull below 7lbs? 6 lbs would be my goal but 6.5 lbs would be totally acceptable too!

Thanks.

-

Springer basepads are better IMO

While you are at it, also add the Springer extended mag release - it makes life much easier and it's production legal

Buy an APEX drop in barrel and you will be amazed how accurate the MP can shoot

-

Fun to play but not accurate because obviously I am human

People who play a lot of video games (including me) will excel at this. Not an accurate measurement of shooting related reaction time IMO

-

-

OK. I got my Limited Pro today. Out of box, the trigger is amazing... 3 lbs 15 oz SA and 9 lbs 5 oz DA.

I took the 1 piece sear in Limited Pro and put it in the Stock 2, well, at least now the T3 disco would allow the safety to be installed and the safety actually works when installed - the holes do align now. DA won't fall but that's expected, obviously I need to fit the T3 disco but it's at least in the gun.

Looking back at my problems, I think the 2-piece sear on the Stock 2 is a major culprit. Will do more testing with the 1 piece sear later.

Right now, I am comparing the 3 different disconnector...

The Stock 2 factory is 1-wing, and the wing is on the left.

The T3 disco is 1-wing, but the wings is on the right.

The Limited Pro factory disco is 2-wing.

Does anyone know why the difference? Could the T3 disco with the wing to the right ever going to work with the Stock 2 2-piece sear (because the factory disco has the wing on the left)?

-

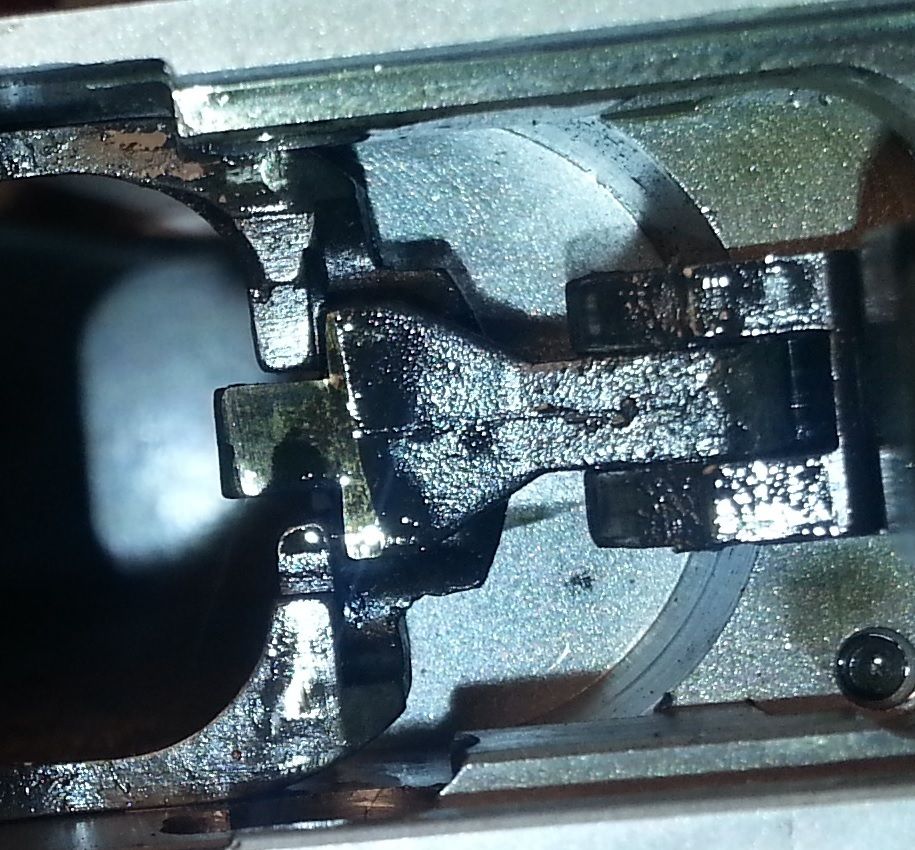

Trying that too. Q - when I put the T3 in, the sear block won't even sit deep enough for the safety pin holes to fully align. I know there are fitting work you posted fir the wings and angles. Is there also need to remove material from the back of the disco to make it slimmer? I have already polished the areas where sear touches the back of the disco.put the t3 in

-

I put on the BIC click pen spring and measured the triggers. Surprisingly, no difference for me.The CZ RP FPS is no 18lbs. Some people use the spring from inside the click pens without issues but I wasn't the ballsy.

What kind of primers are you trying to pop off?

Sent from my GT-N7105 using Tapatalk

-

As the title says, I am only chasing SA now. I am quite happy with 7 lbs DA. However, coming from consistent 3 lbs APEX trigger, I find 3 lbs 12 oz pretty sucky, given 95% of the shots will be affected. I just want to get the SA to be at least as decent as most polymer guns.

Sent from my GT-N7105 using Tapatalk

-

put a cz Reduced firing pin spring on the plunger and polish the crap out of it. Mine had ridges on it so i actually had to use an emory wheel on my dremel to remove the ridges. I polished until it felt smooth to me when compressing. The cz RP FP spring will bring DA down a good amount i believe.

What's the difference between the CZ reduced power FP spring and the Henning plunger spring? Henning is rated 18# I think it is light enough...

http://henningshop.com/products/copy-of-tanfoglio-trigger-plunger-springs-h037

-

Do you have a 1 or 2 piece Sear ??

Get the 1 piece with a CZ sear spring

The 2 piece Sear adds a extra spring ( ounces of added weight )

Thanks. I am currently using the factory 2-piece sear and spring.

Is this the right CZ sear spring to get? https://cajungunworks.com/product/12-sear-spring/

Is this the right 1 piece sear for Tanfo I should get? http://benstoegerproshop.com/eaa-tanfoglio-witness-one-1-piece-sear-9-1/

Thanks again.

-

I am able to achieve 7 lbs DA and 3 lbs 12 oz SA on my Stock 2. Here are the parts I have put in:

1. Titan hammer

2. Xtreme hammer spring (light)

3. Henning 18 lbs trigger bar plunger spring

4. Xtreme FP spring (light)

5. Woff 9 lbs recoil spring

6. Xtreme firing pin

7. Henning guide rod

I have tried CGW reduced power TRS but I found it actually adds 0.5# to DA and did nothing to SA.

Everything else is stock, and all contact areas polished to stainless look following the 101 guide by atlas.

What did I miss here?

Do I need to go crazy on a 4th round polishing?

Should I try T3 disco? That should only help pre-travel with no effect on trigger pulls, correct?

I am trying to achieve 6 lbs DA and 3 lbs SA, which should not be too difficult based on what others have reported here.

The gun runs great 100% ignition with WSP for a few hundred rounds. It's just the trigger... Maybe I should just stop messing with the trigger and just focusing on shooting it?

-

It's a bit odd I know but swapping the pin is the only change. I put on the CGW floating pin, or used a 1/16 punch in place, SA won't fall. I switch back to factory pin, everything works.I've used the CGW pin, and now the Canik variant, and don't see how the pin would cause the problem. Maybe something else changed during disassembly/assembly?

The CGW floating pin is much smaller in diameter than the factory, very similar to 1/16 punch.

Sent from my GT-N7105 using Tapatalk

-

I finally figured out what's wrong. It makes me look stupid, I know.

What happened is that I put on the CGW floating trigger pin for easy swapping in/out parts to test the triggers. I have it there all the time...

Now I put in the real trigger pin, DA/SA works flawlessly!

Thanks for everyone's input and pointers. DIY gunsmithing obviously requires more than just being handy

-

I got .140 x .90 Dawson on Stock 2. I still have to move the sight up 4 inches @ 25 yards.

Shooting 147gr Bayou.

Move the sight up 4 inches?

It's shooting 4 inches low. So I adjusted the rear to hit POA. I was trying to say .140 Dawson front still needs to adjust the rear up.

-

I got .140 x .90 Dawson on Stock 2. I still have to move the sight up 4 inches @ 25 yards.

Shooting 147gr Bayou.

-

The sear assembly would be my guess mostly because you just messed with it and struggled. The large part of it (that holds the hammer back) doesn't seem to be moving enough. I'd take it apart, watch a few more (different) videos and assemble it again. Ill root around in the box of pulled "junk" for an old 2 piece and see if that's it.

oh, try not to worry too much, I've had plenty of fubar moments like this and it's usually pretty easy to correct once the understanding of the problem is found.

Thanks.

I almost bought the Extreme complete sear block to save the struggle and trouble

but I have a Limited Pro incoming today so I can take that sear block and put it in this Stock 2 see if it's truly the sear issue. If it's the sear, I probably would go Extreme.

but I have a Limited Pro incoming today so I can take that sear block and put it in this Stock 2 see if it's truly the sear issue. If it's the sear, I probably would go Extreme.BTW - what's the DA/SA pull like if I swap in all Extreme parts, e.g. complete sear block, trigger bar, disconnector, trigger bar plunger, etc. with other parts polished? It may actually be worth the cost if it can do 6lbs DA and 3lbs SA.

-

I think he is talking about the over travel screw on the trigger. If that is screwed in too far, it can definitely keep the hammer from dropping in SA. It would be possible for the hammer to still drop in DA depending on the fitment of the disco. I would back out the over travel screw on the trigger a bunch and test again. I like to have the screw in about a 1/4 turn less than it takes to feel contact between the hammer and sear when holding the trigger all the way back and manually pulling and releasing the hammer. Contact here may still allow proper function, but can cause your hammer or sear to wear out faster...

I looked at the over travel screw, it is already backed out as much it can, to a point where further backing out would stick the back of that screw out of the trigger surface.

Besides, I had the gun working perfect condition Saturday morning. I have not touched over travel screw.

-

I just took another video.

I can make the SA hammer fall, but I need to push down the trigger bar, while holding it down, squeeze the trigger and hold the trigger. Then I slowly let go of the trigger until I hear 1 click, then press trigger and SA hammer would fall. If I wait for the 2nd click while letting go of the trigger (there would be a total of 2 clicks), then SA hammer would still not fall.

Is it possible I polished the trigger bar too much where it contacts the sear?

-

First off the spring of the sear should be down in that slot, did you screw in the trigger screw too far?

another thing could be when installing the extreme firing pin , you need as well to install the extreme firing pin safety

http://www.ericgrauffelonlineshop.com/en/upper-parts/345-firing-pin-safety.html

Trigger screw - I think CZs have a screw there, but for Tanfos it's just a plunger. I don't think one can insert it too far deep in the hole because the bottom of the hole is frame.

-

First off the spring of the sear should be down in that slot, did you screw in the trigger screw too far?

another thing could be when installing the extreme firing pin , you need as well to install the extreme firing pin safety

http://www.ericgrauffelonlineshop.com/en/upper-parts/345-firing-pin-safety.html

Yes I have the Extreme firing pin safety and spring I did not put on the upper parts for this testing. Is it needed for testing trigger? I will try that.

-

Here is when SA pull does not move the hammer at all:

DAA racer mag pouch for Tanfo large frame mags?

in Tanfoglio (EAA / IFG)

Posted

I use DAA racer mag pouches for MP9s. Now switching to Stock 2, I found these pouches are too small, even after I have replaced the plastic insert with the thinnest one.

What I do notice is that if I take off the round dial all together, just let the thinnest insert backed up by the screw alone without the dial, the mags would fit perfectly.

If anyone here uses DAA racer mag pouches for your large frame mags, what's your experience? Do you somehow "fit" these DAA racer mag pouches? Thanks.