-

Posts

759 -

Joined

-

Last visited

Content Type

Forums

Profiles

Events

Store

Posts posted by Brassaholic13

-

-

-

Just open a production plant already please. Lol what's the per hour count on that ?

From the video, looks like a 14 second cycle time. 3600/14 = 257/hr.

-

Is that a router adapted to the dillon die base ?

No, it's adapted to the trim die and just happens to be the same diameter as the Dillon trimmer and thus utilizes the Dillon vacuum shroud.

-

Brassaholic, any progress on the press?

This one?

-

Cement mixer won't work with stainless pins... Been tried over and over. The stainless pins are heavier and gravitate toward the bottom of the mixer.

It has? I thought it worked, what makes the drum of a cement mixer so much different than all the other drums out there that work?

A cement mixer sits at a 45 degree angle. You could run just the brass with water, Dawn, and Lemishine, but without the pins, it's not going to come out as nice.

For further reading from 2 yrs ago. http://www.ar15.com/forums/t_6_42/368694_Tumble_brass_in_a_cement_mixer.html

-

Cement mixer won't work with stainless pins... Been tried over and over. The stainless pins are heavier and gravitate toward the bottom of the mixer.

-

-

Well of course. If you guys are doing it, then NOBODY, and I mean NOBODY, should ever have an issue, right?

This is why I didn't want to post in this thread.

-

I broke two of the Dillon shell plates. Now, I will admit, I do have a Forcht autodrive with 3-phase motor that I control the speed on the VFD. If a index pawl breaks, or ovals the index pawl pin, and the shell plate does not fully rotate, you're going to dork a Dillon shell plate. They are NOT that rugged.

I purchased a pair of the GS Tool shell plates, which are more robust than the Dillon plates by far, but I had an issue with them. The cases were wobbling in the plate way too much due to bad tolerances. After talking to the owner at GS Tools, he admitted there was human error involved, but had transitioned to CNC machining. He sent me two new plates, and a return shipping label to send the old ones back. Excellent customer service. On par with any I've experienced with Dillon, Hornady, or Lee, and significantly better than CH4D's customer service.

The replacement plates worked as well or better than Dillons, and in the event of an issue, did not bend, break or dent.

I've held off posting here, because I know this will eventually turn into a dick waving thread of who has the better shell plate. Now, you know my experience, for whatever little that is worth.

I would suggest, if you're in question, to try one. If you're not happy, or it doesn't work as advertised, you're covered by Ebay's buyer protection and the good experience of customer service that I had (which may or may not have changed in the past 3 months since I bought mine).

-

On your Lee resizing die. Ditch the o-ring and turn the nut upside down. Works like a charm.

-

If you're pushing the bottom of the primer pocket inward, the case is ruined.

The primer gauge doesn't have to fully engage. Remember, the crimp is only on the outer edge. Gauge a crimped case and notice that the gauge won't fit. Then adjust the swager to where the gauge will enter the case mouth. To verify, use a single stage press to push in a primer, then discard the primer.

-

Maybe submit that, along with an engineering job application (or an invoice), to Hornady. Shouldn't have to re-engineer faulty designs they are profiting from.

-

Any issue? I wouldn't say that. I use the Dillon large pistol plate (same as Hornady) on everything except 9mm/.380.

So, did you ever try the 9mm in the large pistol plate or not?

Yeah, I did, which is why I don't use it.

-

Any issue? I wouldn't say that. I use the Dillon large pistol plate (same as Hornady) on everything except 9mm/.380.

-

I´m pretty sure, that the Dillon case feeder is a good and well engineered product

If you get a good one, yes. I have lots of Dillon case feeders and each has a unique personality. Some are problem children. If people are reporting these other case feeders are worse than Dillon then I'd definitely stay away.

I have a question going the other direction. Are the Hornady case feeders worth the extra money vs the Dillon?

Had a Hornady Lock-N-Load prior to my Dillons. Stay away from that case feeder. Not only is it loud, but it jams far more often than the Dillon. Brass waterfall on a regular basis.

-

Ok so I am familiar with annealing. Why is the question as I am a new to reloading and what I have done has been straight case pistol. Oh and it looks great.

Worth the read: http://www.6mmbr.com/annealing.html

-

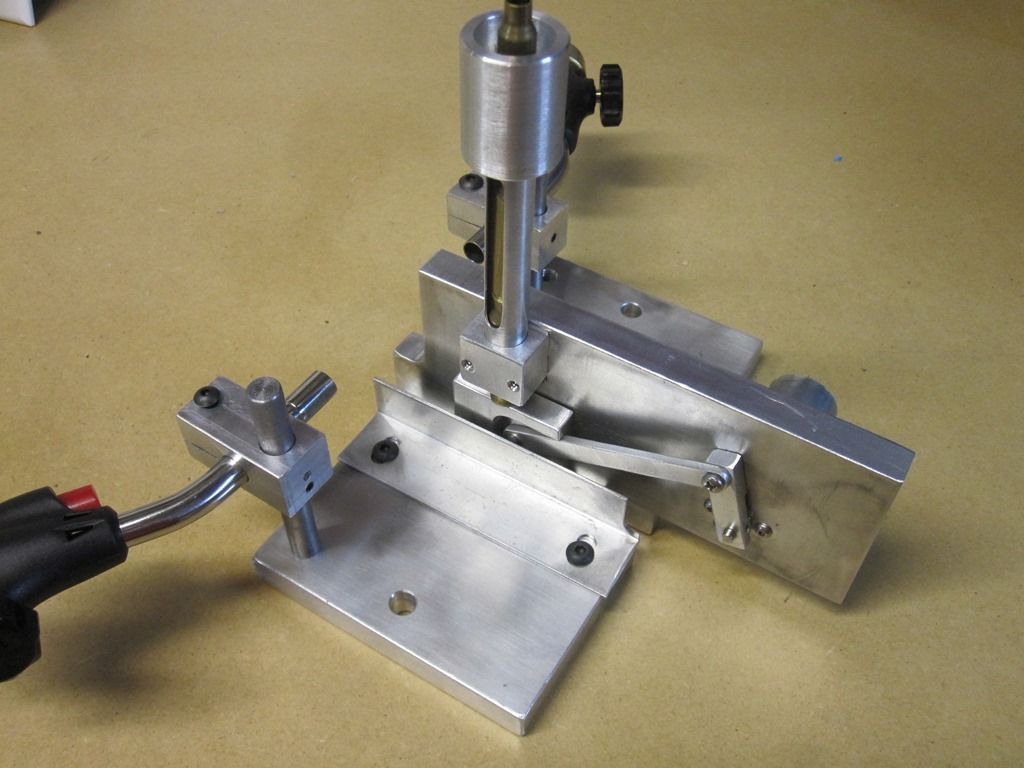

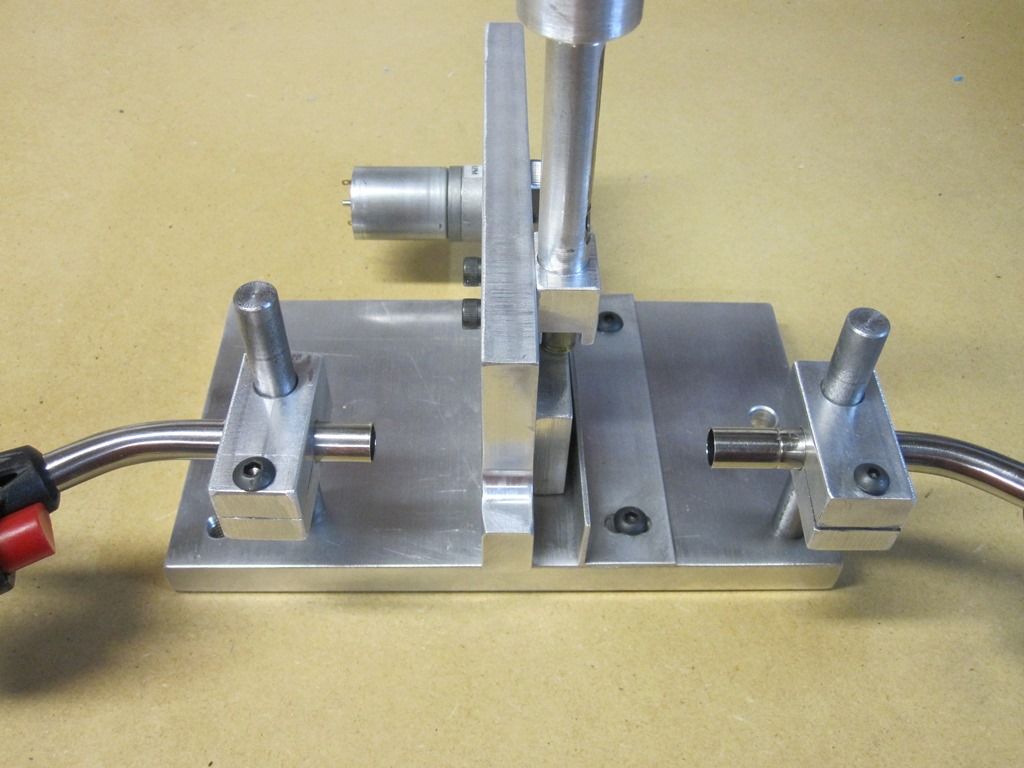

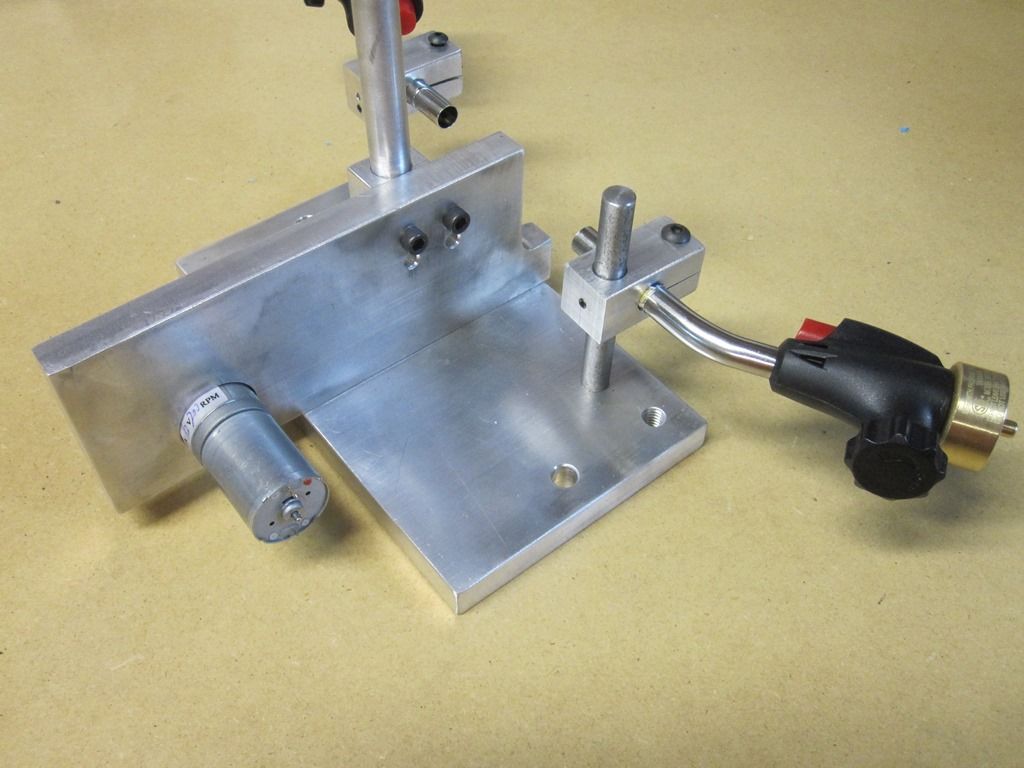

So, being a do it myself kind of guy, and not liking the offerings out there, I decided to make my own annealer, with the CAD help of a friend.

The motor to be used (not in photo) will be 12V DC, 8 RPM, with speed varied by voltage from a 10A power supply.

I just got this done today, and snapped some photos before throwing on some wiring. Will start testing it in the coming week. Should be fairly easy to setup.

Total footprint on bench is 7" x 7" plus the torch overhang. Top adapter is fed by standard Dillon collator tube.

-

http://www.ar15.com/forums/t_6_42/349969__28_00_Bullet_feeder_for_Any_Progressive.html

Mr Bullet Feeder for sure. Hornady feeder is horribly noisy and as stated, has no shut off. If you are thinking about the Mr BF, then skip the Hornady bullet feeding dies. The Mr. BF dies are superior in adjustability...same for the hopper.

-

This helped with my shoulder pain... Stopped it altogether.

is that deprime/sizeing .40 prass, and an alarm for 10mm?

Negative. That's doing .45 ACP, with a decapping pin error detector.

-

This helped with my shoulder pain... Stopped it altogether.

-

Why would you buy that case feeder over a Dillon???????? Aren't you swapping FROM the Lee due to issues? Then you buy a "budget" case feeder? /facepalm

-

Using the right size drop tube with the right size primer?

And, using the right size disk with the right size primer?

-

I wouldn't do it, but that's me. Use a proper separate sizing die to get the head space where you want/need it, then trim with the trim die.

-

For the cost of these commercial reloaders, you could send a video of each to a design firm and have your own made, custom to your needs, for about the same or less total cost.

The last video has a very robust case holder. Notice that as the shell plate rotates, there's no case wiggle when it stops. The downside to these more complex machines is the cost for caliber change over. But, if you're buying a machine for a dedicated caliber....it's a non-issue.

Custom .300 Blackout Roughing Cutter

in non-Dillon Reloading Equipment

Posted · Edited by Brassaholic13

Almost done! Here's a sneak peak.

Need to get the chain hooked up, then wire it up and start testing. Sorry for the crappy cell phone photo.

Front top shelf screws are to hold a piece of music wire to flick the case tops off before the case drops out. Bottom shelf screws are to hold Lexan chutes to guide the scrap and cases to separate bins. Screws on back plate, about midway up are for an aluminum guard I have yet to make to keep my fingers out of the cutting blade (because I'm dumb like that).

Hoping to cut at a rate of 3k/hour.

ETA: Total desktop space... 12" long by 5" deep, plus collator.