TDA

-

Posts

499 -

Joined

-

Last visited

Content Type

Forums

Profiles

Events

Store

Posts posted by TDA

-

-

That's more like it.

I was looking to do the same when I ran across the second Square Deal set up for the caliber I wanted and pretty much new in the box for $275.00.

Space wasn't a problem, so all I have to do is sit down and load without converting anything.

-

I'm not seeing it with my XL650, which is why I asked. Mine may vary a couple of thousandths at the most.

-

These are set to 1.225, but due to mixed brass, some wind up a little shorter/a little longer.

I'm not sure I follow how mixed brass would affect seating depth of the bullet.

The back of the case is against the shell plate and the seating die is against the bullet, so case length should have no relevance. So how does mixed brass make a difference?

-

1.250" here as well, which is .010" short of the rifling on my 1911.

-

Just checked and 4.6 of Red Dot was 169PF.

-

I'm using 4.6 Red Dot @1.140" with Acme coated 180's and getting mid 170's PF from a P226 Sig.

Hercules (Aliant) published data shows a max of 5.0 @ 1.125" for 180JHP.

Edit: My load data for 4.6 is from memory, as I don't have my notes with me, but I'll verify it in the morning just to be sure.

-

I can't type, as it was WST at Gander Mountain.

I have and use WSF regularly for 9mm and it's working well.

I've been trying Clays and Red Dot for .40 and hear good things about WST.

-

I read that as well and was wondering what was up with that...

"Sticky" and "flaky" are far from what I find with N310.

-

I was out running around this morning and passed a Gander Mountain so I decided to stop and see if they had anything interesting.

I always wanted to try some WST, but have never run across any, so I was surprised to see 1lb containers on the shelf.

I was even more surprised to find that it was $40.00 per lb.

and left it on the shelf.

and left it on the shelf. -

Don't worry about the lube groove.

When loaded to 1.250", which is pretty common, there will only be about .030" of shoulder out beyond the case.

You'll need to check to make sure they are not touching the rifling at that length, but it's a good starting place.

-

-

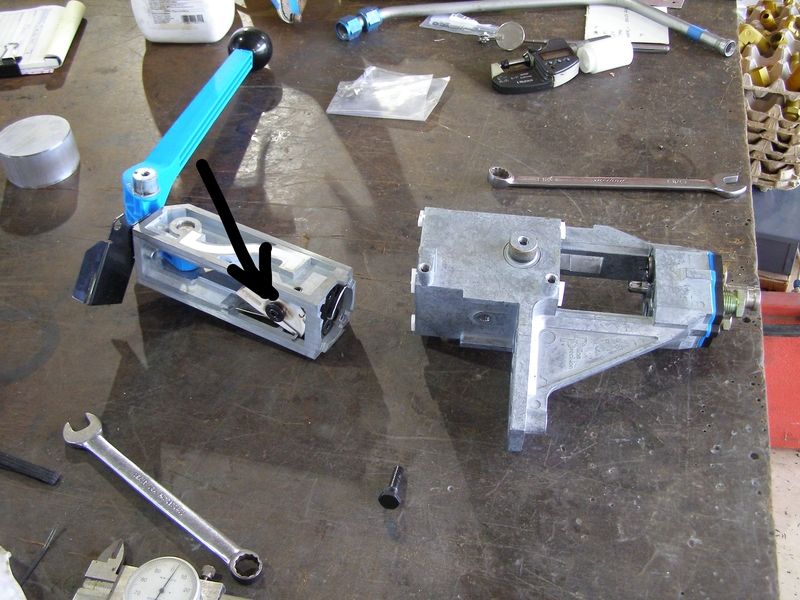

I bought a used one where the cap screw securing pawl assembly to the ram had come loose.

The ram had to be removed to tighten the screw though, as it faces from back to front and is on the rear of the ram.

-

Did you check to see if the screw in the center of the shell plate came loose?

-

I use the Lee for .40 and run all spent ases through it after tumbling and prior to re-loading.

I do it with no lube and it works just fine and is quik and easy.

Uh-oh, the letter "see" just quit working on my keyboard!

-

Yes, as noted above, I have large hands and it was a bit tight loading .45 on the SDB, but not too bad.

.40 and 9mm are no problem at all.

-

I don't load in great quantity, so I can load what I need in 9mm in about the time it would take to convert the .45 ACP XL650 to small primer and set it up for 9mm. Then I would decide to shoot .45 next time and have to convert it all back again...

Actually, i bought a new Square Deal in .45 first, then a 9mm conversion for it. Encountered the problem above, so I ran across another used Square Deal for a good price and bought it so i could have one for large primer, and one for small primer.

Soon after, a friend showed up with a well equipped XL650 someone at his Church was selling as they were getting out of re-loading, so I grabbed it.

I liked the Square Deals so much I couldn't stand to sell them, so I just use them. Other then encountering a few crimped primer cases, I've never had an issue with them. They just run smooth and spit out consistent ammo. Not quite as fast as the 650, but I don't do big volume, so it's more of a convenience thing.

-

I have a 650 and two Square Deal B's.

650 for .45ACP and I have everything for a 9mm conversion, but just never did it.

I load 9mm on one SDB and .40 on the other SDB.

I don't have to do any conversions that way.

-

I'm discovering that certain softer alloy bullets are being re-sized by case tension alone as they are being seated.

Seat a bullet, and without crimping, pull and measure the bullet and compare it to one that has not been seated.

I tried Precision bullets in .40 cal which are .4015" and got severe leading in a couple of Sigs, a M&P, and a Glock 22. (Glock was no surprise)

I switched to Acme coated bullets, which are .401" and they leave the barrel perfectly clean.

You would think that the Precision would be a tighter fit in the barrel and theoretically work better than the Acme bullets.

The difference is that after seating, the Precision were reduced to .400", but the Acme were only reduced to .4015".

I'm looking into a slightly larger expander die (using a Dillon) to relieve a bit of case tension and not constrict the bullet as much.

I just tried the Precisions in my Beretta a couple of days ago and they seem to work in it, which led me to investigate further, finding that the Beretta has a slightly smaller barrel than the other pistols.

-

Look at the primer.your load is probably light, but there is no way to tell without a Crono.

The primer is not an absolute indicator of velocity - MUCH better to have a chrono,

or borrow one for a day.

With all due respect:

The chrono is not an indicator of pressure!

Most here are looking for a specific power factor, so a chrono is a necessity. I would rely more on the primer as an indicator of nearing a pressure problem if I had a choice.

I would suspect that powder manufacturers rely on pressure readings rather that velocity when developing load data. (Not to say that they rely specifically on reading the primer)

I've got Clays that I am trying to use and I have read lots of threads on loads for it in various calibers. On some I've stopped short of what others have claimed to be using due to primers I didn't like the look of, before reaching the power factor/velocity that they claim to be getting. When the primer flattens back out to where the firing pin dimple nearly gets pushed back out, I don't really care what the chrono shows!

When I try a new load, whether "published" of from someone on here, the first thing I do is start below low and fire a round into the dirt and look at the primer. Then work up watching the primer and the chrono.

My method may be way off base, and I'm not claiming that it is the "correct" way to go, but it's working well for me so far!

-

your load is probably light, but there is no way to tell without a Crono.

Look at the primer.

-

Actually, Beretta's have recessed breech faces as well.

-

I prefer powders such as N310, Clays, N320, or Red Dot.

5.0-5.2 of Red Dot spits a 200gr LSWC out of my 1911 at just over 1000fps, cuts a nice clean hole in paper, feels like a .45 load, ejects the case like it should, and I find it to be very accurate.

-

As I said, I have not looked at a CZ, but read the last couple of posts here.

http://www.brianenos.com/forums/index.php?showtopic=217412

Edit: There are also a couple of pics earlier in the thread showing the case sticking up way past the barrel hood.

Seems odd to me as well!

-

Throw away your calipers for measuring crimp and get a single edge razor blade.

Place the sharp edge along the case and hold it up to the light. If the case has any flare at all to it (not enough crimp) you will see it. If you have too much crimp you will see that too as the edge will roll in.

The area of the case where the bullet is presses in should be straight after seating and crimping. No bell left and no turned in edge.

Works for me anyway.

Edit: Forgot to say to check those two cases in an area other than where they got dinged and see if they are not belled slightly.

Strange markings on cases

in 44/45 Caliber

Posted · Edited by TDA

I'd start by putting an index mark on the rounds and stuffing them into the magazine with the mark up.

That way you will at least know where to start looking when you see where the dings are in relation to the index marks.

It looks like they may be only partially chambering and then being stuffed the rest of the way in with the spring.

I realize that it how it works, but it's not happening as smooth as it should.

The mark could be from the edge of the chamber/feed ramp biting into the case.