340Weatherby

-

Posts

31 -

Joined

-

Last visited

Content Type

Forums

Profiles

Events

Store

Posts posted by 340Weatherby

-

-

BTW, my first system is now shipped to the US and is up and running as it should!

-

Could even get a foot pedal to turn it on/off. So you can keep your hands where it matters...

-

You can see my solution here:

Sure, it's still noisy but you are left in peace for 10-20 rounds before hell breaks loose again.

-

You can use a micro switch at the bottom, and a timer relay that will run for as long as you state. Actually you should find a relay that has DC input and AC output.

Like this one: https://www.ebay.com/itm/DC-12V-To-30V-DC-250V-AC-0-60S-Delay-Timer-Switch-Adjustable-NE555-Relay-Module/202512350212

Instead of getting a hard time adjusting the microswitch I would have used a inductive sensor. (Ring sensor)

But instead of NO "Normally Open" you need a sensor that's NC "Normally Closed"

NO = No output voltage when no signal. (No metal in front of sensor)

NC = Output voltage when no signal. (will send signal to relay when no metal is in front of sensor)

Actually the micro switch must also be NC so it will send a signal when there is no brass. (Most has both options on the legs)

-

22 hours ago, hmg1 said:

I am also not an electrical engineer, but I think when a new piece of brass passes the top switch or sensor it would trip the relay.

Can someone point us (me) to a variable timer (1-100? second) that can be started by a switch (mounted near the bottom of the tube) that would power the feeder. Idea is that the bottom switch trips and start the timer to run the feeder. You would set the timer for the shortest duration it takes to fill the tube. You would also bypass the top switch, so you are not cycling the motor. Thanks, HG

Yes, the problem will be that every case falling down the tube will trip the switch. As you state a timer will be a solution to do this a simple way. That's why the Arduino makes it so smooth. The coding will make the system fill the tube all time even if I change caliber.

Here is a manual way of doing it:

-

Download video

-

On 1/29/2019 at 6:22 PM, StealthyBlagga said:

I just count empty primer trays

Well, strange enough I seems to use more primers than reloaded rounds. Or, they tend to be left in the machine due to out of bullets or powder...

-

7 hours ago, jhgtyre said:

No, first I need to Google "Arduino"! It sounds like something you might order at one of those fancy coffee shops, "I'll have a Vente Arduino two creams, hold the sugar".

Well, to put it simple I did it this way, Because I can!

-

The removed cable from the feeder.

-

The inductive ring sensors:

-

Here is a pic how I mounted the Arduino, with the relay inside the case feeder.

-

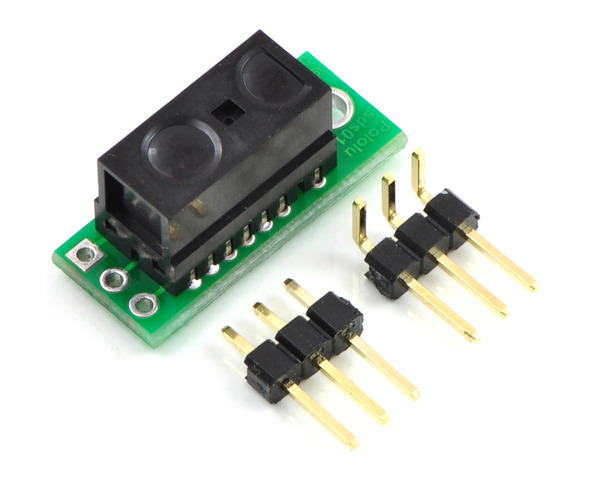

Here is the IR Sensor

So, 5V DC will do just fine like a USB charger to run the sensor. Then you can use what counter you prefer. Sensor is NO. (Normally Open, output 0V)

Maximum range: 10 cm Minimum range: 2 cm Sampling rate: 390 Hz2 Minimum operating voltage: 2.7 V Maximum operating voltage: 6.2 V Supply current: 5 mA3 Output type: digital4 -

First, you need to do some wiring on the 110V/230V system. Then code an Arduino using a PC and wire up the sensors to get it working. To me it's not complicated but you need some technical insight. Playing with 110V/230V is not good if you do any mistakes. Besides that, the rest is simple to do. (I think)

For cost eBay is your friend. You will need the following:

A 12v DC power supply. To drive the sensors and the Arduino

2 inductive sensors. (I use ring sensors, so I can slide them outside the tube.)

1 Solid State Relay DC/AC version.

1 Aduino Uno + a long USB cable. (So you can update the Arduino code if needed)

1 resistor, and some wiring and tape.

1 screw terminal

Cost, not sure but maybe I have used about $ 80 or so. Biggest cost is the sensors.

I'm off for a couple of days, but I will see if I can post some video later of this.

-

Hi, here is a picture of my ammo counter. Using an Arduino, a Digital IR sensor and a PC. The reason for doing it this way, is that most counting systems never count actual rounds reloaded. My sensor triggers on reloaded rounds down the chute. The software is programmed by me as well. Seems to work as intended, but I need to do a lot more testing...

-

On 8/10/2018 at 1:50 AM, PhillySoldier said:

I wish there was an aftermarket part for both the case and bullet feeders that let it drop like a 10-20 at a time instead of running w every darn press pull.

Im no electronics genius but to me would a change from one switch to two. One at the bottom to start when its empty and the current one at the top to stop when filled

Yes, I have such a system. First I removed the micro switch and the low speed system on the switch.(Low speed is just a very big resistor) Using an Arduino, a SSR Relay and two inductive sensors the case feeder will start when the tube is empty. When it's full, the feeder will stop, waiting for it to get empty again. I got it all tucked away inside the housing of the case feeder. (Except the inductive sensors that are attached to the droptube) Makes my day since the all time start and stop drove me crazy. If you take a closer look on the micro switch arm, the motor actually stops and starts again for every case dropping into the tube. Just look on the case feeder plate and you will notice. That's not a good way of doing it if you want the motor to last...

-

This program will run on Microsoft Office as a macro file. So you will need Office installed.

The program imports the CSV file on your SD card and gives it the correct formatting. Then it will adjust the size and insert frames and color.

There is also a option for fonts and adding Load data text.

The program has also a auto update function for future releases.For downloads, go to: Download MagnetoSpeed Tools

YouTube video: https://youtu.be/yIZn7-xzUiM

-

Be aware of shooting over it at a slight angle will make the readings erratic.

-

I have uploaded the pdf to my server.

Download: http://www.weatherby.dk/downloads.php?do=cat&id=3

Filename: diychrono.pdf

-

Interesting chrono.

More info:

-

For sure a SUB Moa group!

-

Updated info:

Downloaded the ProChrono software.

Inside the zip file there is a Mac version!

The download button is at right side bottom of page.

-

Here is what ProChrony says:

To chronograph shotgun loads, stand back at a distance of 5 feet

from the chronograph to the muzzle of the gun. If you stand too far

away, the shot will spread out too far causing inaccurate velocity

readings. Also, the wad will separate from the shot column and may

hit and possibly damage the chronograph. When using sabots or

gas checks, there is a chance they may depart from the projectile

path and hit the chronograph. This may damage the display. See

the CEI Debris Shield in the accessories section of this manual; it

can provide an additional measure of protection. -

You can get 5050 LED (60 led's in 1m. Some have 30led's in 1 m) in 5m lenght at eBay for $11 shipped.

This should be enough even for a Oehler 35!

-

Hi, I'm still looking for a replacement for my Oehler 35P.

I have not found any better chrono at the moment.

Next step is to add IR or LED strips for fixing low light problems.

For now, IR LED is hard to find.

Had big thoughts about Kurzzeit, but I'm not convinced at all.

So, here is my dream Chrono:

Hardware running a fast CPU and a good/big display for showing the values. (at the shooting bench)

It should have a SD/USB port for export of data, and export function to excel as well.

PC interface if you choose to use a PC at the range.

The chrono should have 2 sets of sensors with 3 cells as Oehler has.

That way you could make chrono velocitys at MV and at let's say @ 100/200/300 yards.

The Chrono hardware/software should be capable of calculating bullet BC out of the two readings/distances.

Wireless transfer from sensors to hardware unit. WiFi or Bluetooth would be great.

12V and 110/220V power inlet.

Instead of fumbling with the 9V batteries I think a 12V battery is a better solution.

A small 12V battery will last for ever.

I know this is a tall order, but maybe some day...

Dillon Case Feeder Capacity

in Dillon Precision Reloading Equipment

Posted · Edited by 340Weatherby

Could even use the same system on the bullet feeder...

Sure the dimensions is not similar?, and you can't get it working on the steel tube. (You must have top sensor on the cone before the steel tube)

But, it's just a matter of different dimensions on the sensors. (if needed)