-

Posts

247 -

Joined

-

Last visited

Content Type

Forums

Profiles

Events

Store

Posts posted by g56

-

-

As everyone else said, I remove the whole toolhead and pour into a funnel. Pretty easy.......

I have been doing that way for 18 years, works fine!

So there I am, in my garage, with 1/2lb of TG on my lap, and on the front of my shirt, holding my legs tight together, trying to figure out a way to recover the powder, and most importantly not get it all over the floor. Needless to say I only partially succeded at both.I have only one comment on that....and you don't have pictures!

-

I have three Dillon powder measures, I just got one this week and it has the new bushing, the other ones have the old black washer.

-

I'm trying to find out what kind of knob that is, I looked at my local Lowe's today and they didn't have anything even close. The knobs that I have seen seem to be 3 different types, female threaded, male threaded, or a bushing with a set screw, so I'm having a bit of trouble figuring out what he's buying that can fit on a 7/16" hex nut, and I have to go out of town to get to a Home Depot, might be a while...

-

I'm not a fan of Lee dies, but they do offer a set for 38 S&W, the other alternatives are trying to get something else to work, or special order dies for a lot of money.

-

I was kind of surprised when I first saw it, I was used to the one for pistol calibers, where the powder drop is also the expander, so this one was different in that it's like an inverted funnel, to guide the case neck into the center to receive the powder.

-

I bought this press back in the 80's when I was shooting PPC matches, I loaded many thousands of 38's on it, with excellent results out of my match PPC pistol. I continue to use it to load quite a few 9mm and 45acp on it, but this is my first experience of progressive loading centerfire rifle cartridges.

-

I have adjusted the plate, it looks like it will take care of the problem, I won't know for sure till I load some more, but I need to test the load I was using last night before I load any more. Waiting on the weather!

-

The powder is H335, so it wasn't bridging, it was the case not being lined up with the hole, the powder would fall on the shellplate and make a heck of a mess!

I was thinking about it last night and figured I probably need to tighten down the shellplate some more, I believe that's probably causing the problem.

Thanks for the replies, we seem to be thinking along the same lines!

-

I got a box of goodies last night from Dillon, this afternoon I started setting the 550 up for 223, ran into a problem with the powder measure, sometimes as you raise the ram, the case doesn't line up right, the powder measure dumps the powder all over the shell plate. Then you have a case full of powder all over the place, makes a big mess that's hard to clean up. The rifle cartridges are taller than pistol cartridges, that amplifies any misalignment.

I am wondering if I don't have the powder die adjusted right or ????

-

Thanks for the information Travis, I'll be interested in your results at the range also!

-

-

TBF, when you get those bullets will you check them with a magnet to check for any steel? The way they are being described I wonder if there is any steel in the bullet. When it's cold I shoot at an indoor range, they test all ammo with a magnet before letting it be used, sounds like they have had some problems!

I would appreciate it if you could check them with a magnet and post the result, I'd like to order some, but if they have any steel in the bullet they won't work for me.

-

I wondered if they might be discontinued because of the bargain price, it just means stock up while you can get a bargain!

-

I've been reloading for about 35 years, but I am just getting set up to load 223, I have been reading about cannelures not being uniform in location, even in the same bag or box of bullets. I have read complaints on Remington and Winchester bullets having that problem, and now it seems that even the Hornady's might have the same situation, makes no sense to me.

I guess you just load them all to the same OAL since I would be taper crimping anyway, no matter where the cannelure falls, is that correct?

-

I ran onto that yesterday, here's what the website says:

HORNADY BULK 22 CAL. 224 DIA. 60GR PROTECTED POINT BARRIER W/ CANNELURE 1,000/ BAG---$34 per 1,000

I went to Hornady's website and couldn't find any information on this bullet, it's definitely a good price. Link below:

Hornady bulk 22 cal 60 gr Protected Point Barrier w/cannelure

-

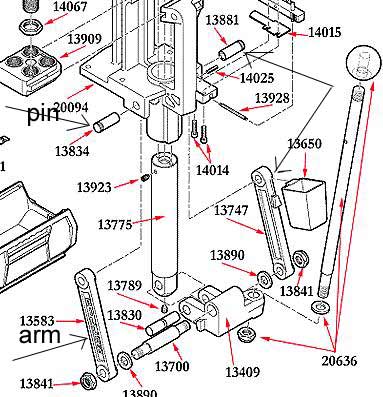

Got a brainstorm, bought a 5/16" bolt, 6" long, the 5/16" fits thru the hole in the right side link pin, punched out the left side pin, the bolt head on the 5/16" bolt is 1/2", exceeded by the points on the head, ground the points off, and had a nice round punch the perfect size to drive out the hollow right side, worked perfectly! Got them out and lubed, partially assembled, just waiting for the alignment tool Dillon said they will send me.

Thanks guys!

-

I've got the press disassenbled and in a padded vice, everything removed except the pivot pins and the link arms, I tried a 1/4" wooden dowel thru the hole in the right side, it wouldn't budge the left one at all. I sprayed it down good with LPS1 last night, it loosened up quite a bit, but I know that's not a fix, just a band aid.

I'll try Dillon's method this afternoon.

BTW, there aren't any oil holes in this press, it's an old 550, I guess they have added oiling holes since then.

The press is a 550 that I bought new in 1985, it's a great press!

-

I noticed my Dillon RL550 was acting a bit stiff, so I started taking it apart to clean and lube the various moving parts. I found the problem, the link arms are really stiff, I can't find a way to remove them to lube them, Dillon's website says to grease them but doesn't tell you how to get them out, and I don't want to damage anything.

How do you remove the link arm pins for lubrication?

-

A lot of the question on brass life is how hot the case is loaded, if it's a hot load, not many times, a milder load can double the life of the case. On rifle cases be sure to check the over all length (OAL) each time.

-

I have been reloading for about 35 yrs, I started out with a Lyman open face C press, a pretty good basic press, and Lyman dies, I felt they were pretty good quality. The biggest disadvantage to a C press is it flexes on rifle loads, so I upgraded to a RCBS Rock Chucker, a great press. Eventually I got into serious Police pistol competion and went to the Dillon 550, I love it! Over those years I had bought loading dies from Lyman, RCBS, Pacific, Lee, and then Dillon. Comparing the Lee dies to those others, the Lee's are poorly made and pretty lightweight, definitely built down to a price. Loading pistol calibers thru a single stage press with a Lee die, took at least twice as much pressure on the presses lever arm than the other brands of dies. Over the years I have replaced every single item that was Lee brand with better quality item. There is a tendency for someone new to buy for price alone, that is significantly more expensive than buying a quality item in the first place, I know a lot about that because I have done it more than once!

-

I started using a Dillon 550 about 18 years ago, I am extremely happy with it. The Square Deal is somewhat limited in what it can do, it's probably a good started press, but many people will be moving up from that point, so it will be cheaper in the long run to go ahead and get a 550B.

-

Just for information:

I believe the difficulties are due to the embedded music on the page. I have noticed that pages with embedded music tend to hang up Internet Explorer, I clicked on 3 different pages, 2 of the 3 had embedded music and hung the browser, 1 didn't and loaded quickly with no problems.

I have noticed the same problem on other websites that have the music, in my case I am using IE6 on a DSL line, as soon as the page starts to load the browser hangs, it's stuck, you can't do anything, you can't even escape the page, after about 2-3 minutes it finally starts working again.

Latest 550b From Our Host (reloading Porn :) )

in Dillon Precision Reloading Equipment

Posted

I'm sorry...that bench is way too neat, you have to dump some "stuff" on it to make it look right!

Seriously, nice set up!